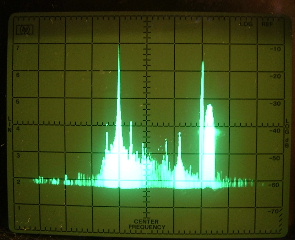

A picture of it working

|

End Result |

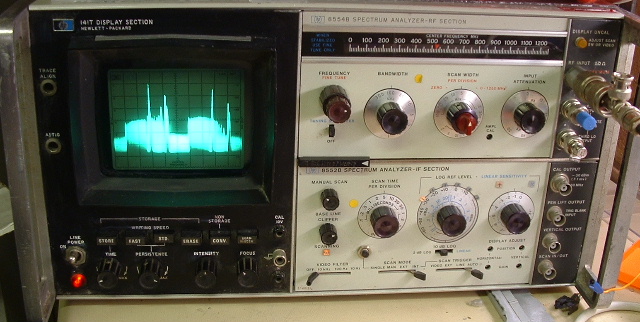

What I started with

|

In the beginning |

What it was like

|

First

Impressions |

The first fault

|

No_tuning

|

| The most obvious problem |

Burnt_resistors_in_the_power_supply_

|

Locating service manuals on US Army website

|

US_Army_to_the_rescue

|

Choosing new resistors

|

Resistor_Replacement

|

Another fault on the timebase unit

|

Almost_Short_Circuit

|

Mistake

|

More_smoke

|

Finally spotted another mistake

|

Similar_coloured_wires_again

|

Fatal flaw exposure after...

|

I_did_up_all_the_screws...

|

The last fault

|

Holdoff_timing_leakage

|

Conclusion

|

Working_still

|

Some time later. Continued

problems fixed and outstanding

|

In_use

|

| More In use Jan 2007 |

More In Use |